The ClearSpan Cold Formed Steel Building is an efficient, economical alternative to traditional pre-engineered metal buildings (PEMBs). These structures are designed with precision roll-formed components and can be engineered quickly, providing significant savings on cost and labor.

ClearSpan’s Cold Formed Steel Building is manufactured using precision roll forming instead of welding, allowing customers to get a beautiful, cost-effective metal building that prioritizes strength and speed. Cold rolled steel buildings offer reduced foundation requirements, simplified installation and can be engineered and delivered in as little as 4 weeks, producing one of the industry’s shortest construction timelines. With ACT software, ClearSpan can ensure each structure is designed with the utmost strength and reliability.

ClearSpan offers cold formed buildings in widths ranging from 3’ to 100’, heights up to 30’ and in unlimited lengths. Customers are able to take advantage of extensive customization, incorporating mezzanine floors, lean-tos, eaves and more to create the ideal structure for their specific requirements. These buildings are suited for a wide range of agricultural, commercial and industrial applications, and by engineering them to local wind and snow loads across the U.S. and Canada, ClearSpan customers always know they’re getting a cold formed steel building of the highest quality.

Cold Formed Building Profiles And Finishes

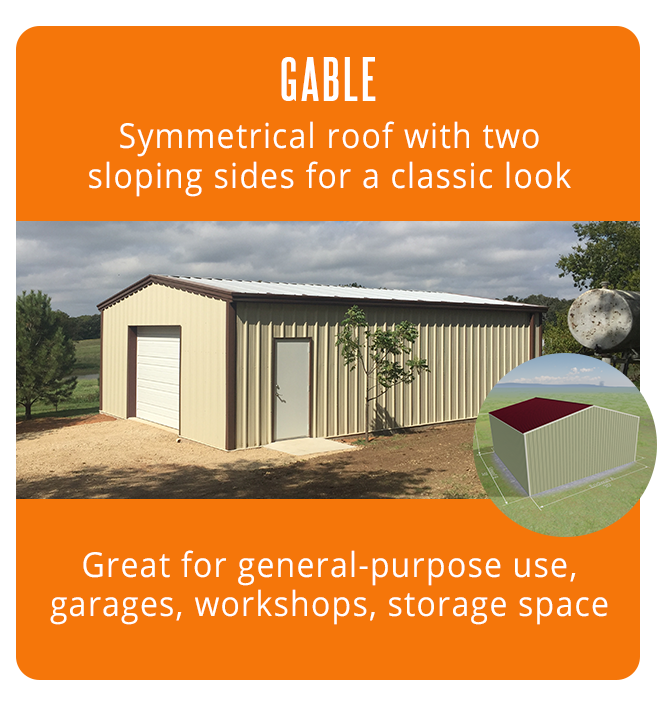

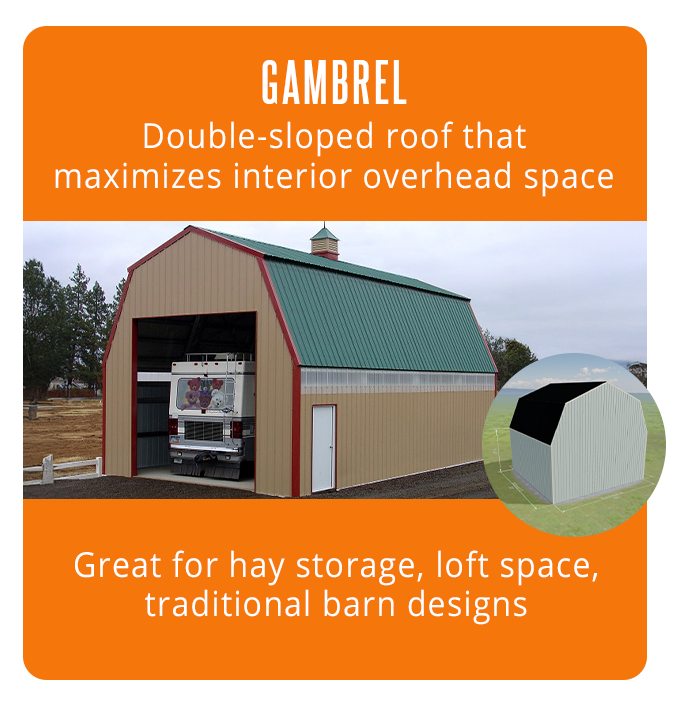

In addition to extending the life of each building, galvanized cold rolled steel framing provides a clean, finished appearance inside and out. With no unsightly blemishes as a result of welding, cold formed metal buildings offer exceptional aesthetic value, while also minimizing long-term maintenance. For an attractive, dependable metal building that saves time and money, the ClearSpan Cold Formed Steel Building presents an ideal solution. Below are some of the profiles ClearSpan offers:

Dependable Cold Formed Steel Manufacturers

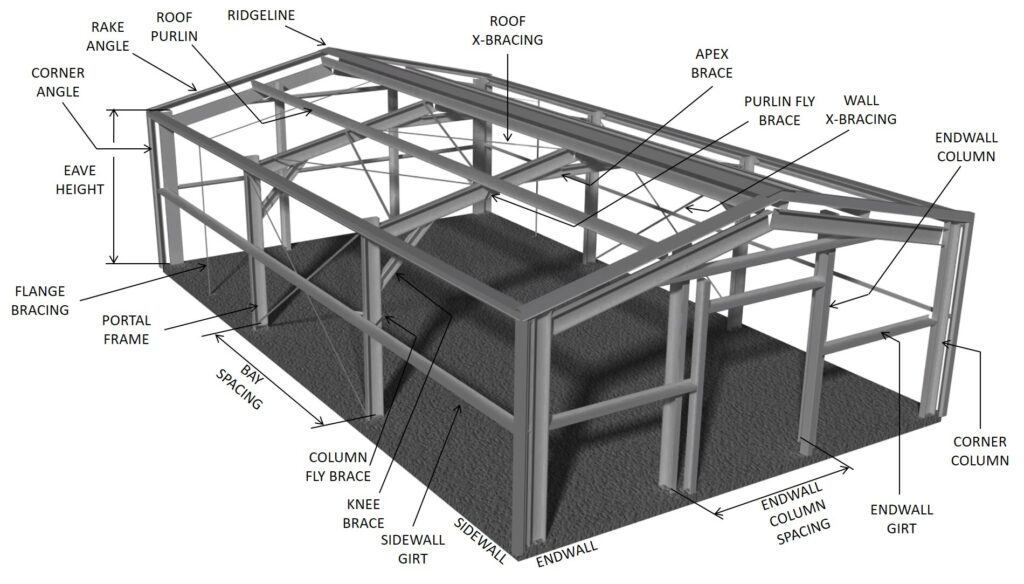

Each cold formed steel building is manufactured in ClearSpan’s Dyersville, Iowa facility with roll-formed steel components. This cost-effective process is done using roll forming machines, which take steel coils and run them through a series of rollers to mold them into specific shapes. Cold rolled steel building systems consist of straight columns and rafters, as well as a series of knee and apex braces. The primary steel framing on each building ranges from 16 gauge to 10 gauge and varies from 4” to 24” in depth and 2-1/2” to 5” wide.

ClearSpan’s Dyersville, Iowa manufacturing facility is state-of-the-art, employing the latest automations and technology to deliver high-quality buildings in a rapid timeframe. ClearSpan produces cold formed steel, fabric and metal I-Beam and fabric and metal truss buildings that can be tailored to nearly any application across dozens of industries. Being centrally located in the U.S., ClearSpan is also able to streamline distribution by mitigating transportation requirements, passing down cost and time savings to each customer and their project.

Streamlined Construction And Reduced Foundation Requirements

During installation, cold formed steel buildings are bolted and screwed together on-site using pre-drilled plates, which requires no welding or heavy equipment. Additionally, unlike traditional PEMBs that require pre-set anchor bolts and structural slabs, these buildings attach to slab, pier or strip foundations using post-installed anchors. Engineered foundation plans are supplied with every kit, and the reduced weight of the frame means less concrete is required overall – typically 20-25% less than comparable steel buildings. These features not only speed up construction, but also allow the installation process to be completed with a smaller crew, less machinery and at a lower cost.

To start designing your ClearSpan Cold Formed Steel Building, Request a Quote today.